- Home

- Spray Foam

- Air Sealing

- Commercial Roofing

- Ice Damming

- Attic

- Basement

- Crawl Space

- Roof Coatings

- Our Work

- About Us

Reed's Sprayfoam Insulation is proud to serve the following cities

Reed's Sprayfoam Insulation is proud to serve the following cities

- Aberdeen

- Accoville

- Adams

- Addyston

- Adelphi

- Afton

- Ages Brookside

- Albany

- Alkol

- Allen

- Allen Junction

- Alpha

- Alum Creek

- Amberley

- Amelia

- Amesville

- Amherstdale

- Amigo

- Anawalt

- Andersonville

- Andover

- Annville

- Appalachia

- Apple Grove

- Argillite

- Arjay

- Arkoe

- Arlington Heights

- Arnoldsburg

- Artemus

- Arthur

- Ary

- Ashcamp

- Ashford

- Ashland

- Ashton

- Ashville

- Athalia

- Athens

- Augusta

- Auxier

- Avawam

- Avondale

- Bainbridge

- Baisden

- Bakersville

- Bancroft

- Banner

- Barboursville

- Barbourville

- Bartley

- Batavia

- Bath

- Baxter

- Bean Station

- Bear Branch

- Beattyville

- Beauty

- Beaver

- Beaver Pike Estates

- Bee

- Belcher

- Belfry

- Belle

- Belpre

- Ben Hur

- Benham

- Bentonville

- Berea

- Berry

- Berwind

- Bethel

- Bethelridge

- Betsy Layne

- Beverly

- Bevinsville

- Bexley

- Bidwell

- Big Creek

- Big Laurel

- Big Rock

- Big Sandy

- Big Stone Gap

- Bighill

- Bim

- Bimble

- Birchleaf

- Blackberry

- Blackey

- Blacklick Estates

- Blackwater

- Blaine

- Blair

- Bledsoe

- Bloomingrose

- Blount

- Blountville

- Blue Ash

- Blue Creek

- Blue Jay

- Blue River

- Bluff City

- Bob White

- Bobo

- Bonds Trailer Court

- Bonnyman

- Booneville

- Boons Camp

- Borderland

- Bourneville

- Bradfordsville

- Bradshaw

- Branchland

- Breaks

- Brecon

- Breeden

- Brenton

- Brice

- Briceville

- Bridgetown

- Bristol

- Bristol Village

- Brodhead

- Bronston

- Bruno

- Bryants Store

- Buchanan

- Buchtel

- Buckhorn

- Bud

- Buffalo

- Buford

- Bulan

- Bulls Gap

- Burdine

- Burkesville

- Burlington

- Burnside

- Burnsville

- Busy

- Butler

- Bybee

- Byington

- Bypro

- Cabin Creek

- Calvin

- Camp

- Camp Dennison

- Campbellsville

- Campton

- Canada

- Canal Winchester

- Cannon

- Carbon Hill

- Carlisle

- Carrie

- Caryville

- Catlettsburg

- Cawood

- Cedar Fork

- Cedar Grove

- Centerville Village

- Ceredo

- Chapmanville

- Chappell

- Charleston

- Chattaroy

- Chauncey

- Chavies

- Cherry Fork

- Cherry Grove

- Chesapeake

- Cheshire

- Cheviot

- Chillicothe

- Chilo

- Chuckey

- Church Hill

- Cincinnati

- Circleville

- Clairfield

- Clarksburg

- Clarktown

- Clay City

- Clayhole

- Clear Fork

- Clearfield

- Clendenin

- Cleves

- Clinchco

- Clinton

- Clintwood

- Closplint

- Clothier

- Coal Grove

- Coal Mountain

- Coalgood

- Coalton

- Coeburn

- Coldiron

- Coldstream CDP

- Columbus

- Combs

- Comettsville

- Comfort

- Commercial Point

- Concorde Hills CDP

- Coolville

- Coopersville

- Cora

- Corbin

- Corinne

- Corryton

- Cosby

- Costa

- Covedale

- Covel

- Crab Orchard

- Cranks

- Crommona

- Crown City

- Crum

- Cucumber

- Culloden

- Cumberland

- Cumberland Gap

- Cyclone

- Cynthiana

- Daleyville

- Dana

- Dandridge

- Danville

- Darbydale

- Darbyville

- Davenport

- David

- Davin

- Davy

- Dawes

- Dawsons MH Park

- Day Heights

- Dayhoit

- Deane

- Debord

- Deer Park

- Del Rio

- Delbarton

- Delhi Hills

- Delphia

- Delshire CDP

- Dema

- Denniston

- Dent

- Denton

- Derby

- Devola

- Dewitt

- Dice

- Dillonvale

- Dingess

- Dover

- Drift

- Dry Ridge

- Dry Run

- Drybranch

- Dryden

- Dublin

- Duff

- Duffeld

- Dunbar

- Dungannon

- Dunlap

- Dunlow

- Dunnville

- Dwale

- Dwarf

- Eagan

- East Bank

- East Bernstadt

- East Lynn

- East Point

- East Stone Gap

- Eastem

- Eckman

- Edgarton

- Eidson

- Elbert

- Eleanor

- Elgin

- Elizabethton

- Elizabethtown

- Elkfork

- Elkhorn

- Elkhorn City

- Elkview

- Elm Grove

- Elmwood Place

- Emerson

- Emmalena

- Eolia

- Ermine

- Erwin

- Eskdale

- Essie

- Ethel

- Eubank

- Evarts

- Evendale

- Ewing

- Ezel

- Fairfax

- Fairfield

- Falcon

- Fall Branch

- Falling Rock

- Falmouth

- Fanrock

- Fayetteville

- Fedscreek

- Felicity

- Ferguson

- Finneytown

- Fisty

- Flag Pond

- Flat Lick

- Flatgap

- Flatwoods

- Flemingsburg

- Forest Hills

- Forest Park

- Forestville

- Fort Blackmore

- Fort Gay

- Foster

- Fourmile

- Frakes

- Frametown

- Frankford

- Frankfort

- Franklin Furnace

- Fraziers Bottom

- Freebum

- Frenchburg

- Friendship

- Fruit Hill

- Gahanna

- Gallagher

- Gallipolis

- Gallipolis Ferry

- Gamer

- Garrett

- Garrison

- Gary

- Gate City

- Gatlinburg

- Gays Creek

- Genoa

- Georgetown

- Germantown

- Germany

- Gibson Trailer Park

- Gilbert

- Girdler

- Givens

- Glasgow

- Glen Fork

- Glen Jean

- Glen Rogers

- Glendale

- Glenwood

- Glouster

- Golf Manor

- Gordon

- Goshen

- Grandview

- Grandview Heights

- Gravel Switch

- Gray

- Grays Knob

- Grayson

- Green Acres

- Green Road

- Greeneville

- Greenfield

- Greenhills

- Greenup

- Greggs

- Greggs Hill

- Grethel

- Griffithsville

- Groesbeck

- Grooms MH Park

- Grove City

- Groveport

- Grundy

- Gulston

- Gunlock

- Hallie

- Hamden

- Hamersville

- Hamlin

- Hampton

- Handley

- Hanging Rock

- Hanover

- Hansford

- Hansoford

- Happy

- Hardy

- Hargerhill

- Harlan

- Harold

- Harrisburg

- Harrison

- Harrodsburg

- Harrogate

- Hartford

- Harts

- Hatch

- Haverhill

- Haydenville

- Haysi

- Hazard

- Hazel Green

- Heidrick

- Heiskell

- Helenwood

- Hellier

- Helton

- Hemshaw

- Henderson

- Henlawson

- Hensley

- Herndon

- Hewett

- Hi Hat

- Hide-A-Way Hills

- Higginsport

- Highland

- Highland Holiday

- Highpoint

- Hilliard

- Hillsboro

- Hiltons

- Hindman

- Hinkle

- Hitchins

- Hockingport

- Holden

- Holmes Mill

- Hometown

- Hooven

- Huber Ridge

- Huddy

- Hueysville

- Hugheston

- Hulen

- Huntington

- Huntsville

- Hurley

- Hurricane

- Hustonville

- Hyden

- Iaeger

- Idaho

- Ikes Fork

- Inez

- Ingram

- Institute

- Ironton

- Irvine

- Isaban

- Isom

- Isonville

- Itmann

- Ivel

- Jackhorn

- Jacksboro

- Jackson

- Jacksonville

- Jamestown

- Jasper

- Jeff

- Jefferson City

- Jeffersonville

- Jeffey

- Jellico

- Jenkinjones

- Jenkins

- Jeremiah

- Jesse

- Johnson City

- Jolo

- Jonesborough

- Jonesville

- Julian

- Junction City

- Justice

- Kanauga

- Keaton

- Keavy

- Keen Mountain

- Kenna

- Kenova

- Kenvir

- Kenwood

- Keokee

- Kermit

- Kerr

- Kettle Island

- Kiahsville

- Kilgore Estates

- Kimball

- Kimper

- Kincaid Springs

- Kings Mountain

- Kingsport

- Kingston

- Kistler

- Kite

- Kitts Hill

- Knoxville

- Kodak

- Kopperston

- Krypton

- Kyle

- Kyles Ford

- La Follette

- Lackey

- Ladd

- Lake

- Lake City

- Lake Darby

- Lake Lorelei CDP

- Lake View Heights

- Lake Waynoka CDP

- Lake White MH Park

- Lancaster

- Langley

- Lapperell

- Latham

- Laurel Bloomery

- Laurelville

- Lavalette

- Lawrenceburg

- Lebum

- Leesburg

- Lejunior

- Lenore

- Leon

- Lesage

- Letart

- Letcher

- Lewisburg

- Lexington

- Liberty

- Lick Creek

- Lily

- Limestone

- Lincoln Heights

- Lincoln Village

- Linefork

- Linn

- Littcarr

- Little Hocking

- Livingston

- Lockbourne

- Lockland

- Logan

- Logan Elm Village

- London

- Lone Mountain

- Lorado

- Lost Creek

- Louisa

- Loveland

- Loveland Park

- Lovely

- Lowell

- Lower Salem

- Lowmansville

- Loyall

- Lucasville

- Luttrell

- Lybum

- Lynch

- Lynchburg

- Lynco

- Maben

- Mack

- Macksburg

- Mackville

- Madeira

- Madison

- Majestic

- Mallie

- Mallory

- Mammoth

- Man

- Manchester

- Marble Cliff

- Marianna

- Mariemont

- Marietta

- Martha

- Martin

- Mary Alice

- Mascot

- Mason

- Matamoras Village

- Matewan

- Matheny

- Mavisdale

- Maxie

- Maybeury

- Mayking

- Maynardville

- Mayslick

- Maysville

- McAndrews

- McArthur

- McCarr

- McClure

- McDermott

- McDowell

- McGraws

- McKee

- McKinney

- McRoberts

- Meally

- Meane

- Means

- Melvin

- Miami

- Miami Heights

- Miamitown

- Miamiville

- Middleburg

- Middleport

- Middlesboro

- Midkiff

- Midway

- Milford

- Millfield

- Milligan College

- Millstone

- Milton

- Minerva

- Minerva Park

- Minford

- Minnie

- Miracle

- Mistletoe

- Mize

- Mohawk

- Monfort Heights

- Montgomery

- Monticello

- Moorefield

- Mooresburg

- Morehead

- Morgantown

- Morristown

- Moscow

- Mosheim

- Mount Alto

- Mount Carmel

- Mount Gay

- Mount Healthy

- Mount Healthy Heights

- mount lookout

- Mount Olivet

- Mount Orab

- Mount Repose

- Mount Sinai

- Mount Sterling

- Mount Vernon

- Mountain City

- Mountain Home

- Mousie

- Mouthcard

- Mowrystown

- Mozelle

- Mulberry

- Mullens

- Murray City

- Myra

- Nace Corner

- Nancy

- Naugatuck

- Nellis

- Nelsonville

- Neon

- Neville

- New Albany

- New Baltimore

- New Boston

- New Burlington

- New Haven

- New Holland

- New Market

- New Marshfield

- New Richmond

- New Tazewell

- Newcomb

- Newfain

- Newhall

- Newport

- Newtonsville

- Newtown

- Nicholasville

- Nickelsville

- Nitro

- Nora

- Norris

- North Bend

- North College Hill

- North Matewan

- North Spring

- Northbrook

- Northfork

- Northgate

- Norton

- Norwood

- Oak Hill

- Oak Ridge

- Oakwood

- Obetz

- Oceana

- Oil Springs

- Oilve Hill

- Olympia

- Omar

- Omega

- Ona

- Oneida

- Orgas

- Orient

- Orlando

- Ottawa

- Otway

- Owensville

- Owingsville

- Pageton

- Paint Lick

- Paintsville

- Panther

- Paris

- Parkers Lake

- Parksville

- Parrottsville

- Partridge

- Pathfork

- Patriot

- Paynesville

- Peach Creek

- Peck

- Pecks Mill

- Pedro

- Peebles

- Pennington Gap

- Perryville

- Peytona

- Phelps

- Phyllis

- Pickerington

- Pigeon Forge

- Pike

- Piketon

- Piketon Trailer Court

- Pikeville

- Pilgrim

- Pilgrims Knob

- Pinch

- Pine Knot

- Pine Ridge

- Pine Top

- Pineville

- Piney Flats

- Pinsonfork

- Pioneer

- Pippa Passes

- Pirates Cove

- Plainville

- Pleasant Hills

- Pleasant Run

- Pleasant Run Farm

- Pleasant Valley

- Poca

- Point Pleasant

- Pomeroy

- Pond Gap

- Poplar Grove

- Portsmouth

- Pound

- Powder Springs

- Powell

- Pratt

- Premier

- Premium

- Prestonsburg

- Prichard

- Printer

- Proctorville

- Pruden

- Putney

- Quincy

- R And J MH Park

- Raccoon

- Racine

- Ragland

- Ranger

- Ransom

- Rarden

- Raven

- Ravencliff

- Ravenna

- Rawl

- Raysal

- Reading

- Red House

- Red Jacket

- Redfox

- Regina

- Rehm

- Remington

- Reno

- Revelo

- Reynoldsburg

- Ricetown

- Richmond

- Richmond Dale

- Ridgeview

- Rio Grande

- Ripley

- River

- Riverdale

- Riverlea

- Riverview MH Park

- Riviera Park

- Roan Mountain

- Roark

- Robbins

- Robinson Creek

- Rock Camp

- Rock View

- Rockbridge

- Rockholds

- Rocky Fork Point

- Roderfield

- Rogers

- Rogersville

- Rome Village

- Rose Hill

- Rosemount

- Rossmoyne

- Rousseau

- Rowdy

- Rowe

- Roxana

- Royalton

- Rush

- Russell

- Russell Springs

- Russellville

- Rutland

- Rutledge

- Sabine

- Sadieville

- Saint Albans

- Saint Bernard

- Saint Charles

- Saint Martin

- Saint Paul

- Salem Heights

- Salt Lick

- Salvisa

- Salyersville

- Sandgap

- Sandstone

- Sandy Hook

- Sarah Ann

- Sardinia

- Sargents

- Sassafras

- Saul

- Saulsville

- Scalf

- Science Hill

- Scioto Furnace

- Sciotodale

- Scott Depot

- Scottown

- Scuddy

- Seaman

- Seco

- Seth

- Sevierville

- Sextons Creek

- Seymour

- Shady Valley

- Sharonville

- Sharples

- Sharps Chapel

- Sharpsburg

- Shawanee

- Shawnee CDP

- Shelbiana

- Shelby Gap

- Sherwood

- Shoals

- Shortt Gap

- Shyville

- Sidney

- Siler

- Silverton

- Simon

- Sinking Spring

- Sitka

- Sixteen Mile Stand

- Skyline Acres

- Slade

- Slemp

- Smilax

- Sneedville

- Sod

- Somerset

- Sophia

- South Bloomfield

- South Charleston

- South Point

- South Portsmouth

- South Salem

- South Shore

- South Webster

- South Williamson

- Southside

- sparta

- Speedwell

- Spellman Crossing

- Springdale

- Springfield

- Spurlockville

- Squire

- Staffordsville

- Stambaugh

- Stamping Ground

- Stanford

- Stanton

- Stanville

- Steams

- Steele

- Stephenson

- Stewart

- Stinnett

- Stockdale

- Stollings

- Stone

- Stoney Fork

- Stopover

- Strawberry Plains

- Strunk

- Sumerco

- Summerside

- Summersville

- Surgoinsville

- Switchback

- Switzer

- Sylvester

- Syracuse

- Tad

- Talbott

- Tarlton

- Tatesville

- Taylor Creek CDP

- Tazewell

- Teaberry

- Teays

- Telford

- Tennyson

- Terrace Park

- The Plains

- The Village Of Indian Hill

- Thelma

- Thorn Hill

- Thornton

- Thorpe

- Thousandsticks

- Thurman

- Tollesboro

- Tomahawk

- Topmost

- Tornado

- Totz

- Trade

- Tram

- Trimble

- Trosper

- Tuppers Plains

- Turpin Hills

- Turtle Creek

- Tutor Key

- Twilight

- Twin Mills MH Park

- Tyner

- Uneeda

- Unicoi

- Upper Arlington

- Urbancrest

- Valley View

- Van

- Van Lear

- Van Meter

- Vanceburg

- Vancleve

- Vansant

- Varney

- Verdunville

- Verner

- Versailles

- Vest

- Vicco

- Vincent

- Vinton

- Viper

- Virgie

- Waco

- Wakefield

- Walker

- Wallingford

- Wallins Creek

- War

- Warfield

- Warriormine

- Washburn

- Washington

- Watauga

- Waterford

- Waterloo

- Waverly

- Waverly Estates

- Waverly Gables

- Waverly Heights

- Waverly MH Park

- Waverly Place

- Wayland

- Wayne

- Waynesburg

- waynoka

- Webbville

- Weber City

- Weeksbury

- Welch

- Wellington

- Wellston

- Wendover

- West Columbia

- West Hamlin

- West Liberty

- West Portsmouth

- West Somerset

- West Union

- West Van Lear

- Westerville

- Wetmore

- Whamcliffe

- Wharton

- Wheelersburg

- Wheelwright

- Whick

- White Oak

- White Pine

- Whitehall

- Whitesburg

- Whitesville

- Whitewood

- Whitley City

- Whitman

- Wilcoe

- Wilkesville

- Wilkinson

- Williamsburg

- Williamson

- Williamsport

- Willow Wood

- Wilmore

- Wilsondale

- Winchester

- Windsor

- Winfield

- Winifrede

- Wise

- Withamsville

- Wittensville

- Wolford

- Woodbine

- Woodlawn

- Woodville

- Woollum

- Wooton

- Worthington

- Wurtland

- Wyco

- Wyoming

- Yawkey

- Yeaddiss

- Yerkes

- Yolyn

- Yosemite

- Zahns Corners

- Zaleski

- Zoe

Crawl Space Insulation Near Charleston, Lexington, Georgetown & Johnson City

Ward off mold & moisture damage and boost indoor air quality with the right crawl space insulation

Crawl space insulation is important. A number of comfort and energy problems can be caused by poor quality crawl space insulation.

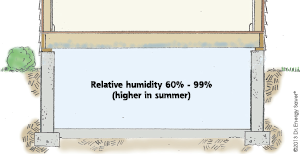

In addition to installing the right type and correct amount of insulation, it is also important that the insulation be installed correctly. The crawl space can be wet and damp, so the insulation installed must be able to hold up in these conditions.

The experts at Reed's Sprayfoam Insulation will inspect the crawl space, seal air leaks, and install high-performance insulation to help improve the comfort and energy efficiency of homes throughout Lexington, Charleston, Georgetown, Johnson City, Louisa, Nicholasville, Hurricane, Chesapeake, Somerset, South Point, Middlesboro and nearby Kentucky, West Virginia and Ohio, Tennessee.

Indicators of crawl space insulation issues:

-

The floor above the crawl space is unpleasantly cold in wintertime.

Crawl spaces, especially those with dirt floors or moisture problems, are wet in summer and cold in winter! Crawl space wall and floor insulation can solve all that!

- During cold weather, you have to keep the heat going nearly all the time to be comfortable in rooms directly above the crawl space.

- Mice or other pests have taken up residence in fiberglass insulation installed between joists in the crawl space.

- Fiberglass batt insulation has fallen out of place from between floor joists in the crawl space.

- The crawl space smells moldy or has visible signs of mold.

- The crawl space is damp all the time.

Many homes have the wrong type of crawl space insulation in Richmond, Ashland, Frankfort, Barboursville, Huntington, Paintsville, Mt. Sterling

The old-fashioned way to insulate a crawl space was to install fiberglass batt insulation between joists and vent the crawl space so outside air could circulate beneath the house.

Unfortunately, this combination usually leads to the problems listed above. Fiberglass insulation doesn’t respond well to the moist conditions that can be found in a crawl space.

The cotton-like material absorbs moisture, gets soggy, compresses and loses R-value. Fiberglass batts often end up on the crawl space floor in a soggy mess. The main advantage of fiberglass insulation –low cost—is totally negated when the material ceases to perform its main function.

Benefits of Rigid Foam Crawl Space Insulation

- Secure and dependable. Unlike fiberglass insulation, rigid foam won’t compress, fall out of place or lose its R-value over time. It’s definitely a “once-and-done” improvement.

- Efficient air sealing. When joints between foam panels are taped, rigid foam stops air leaks that can waste energy. Fiberglass insulation can’t stop air movement.

- Moisture-proof. Rigid foam won’t absorb moisture or be damaged by it.

- Resistant to mold. Mold can’t take hold on rigid foam because it contains no organic food source and it doesn’t hold moisture.

- Improved ductwork performance. Ducts located in the crawl space benefit from rigid foam installed against crawl space walls.

Rigid foam panels exceed fiberglass performace in the crawl space

Good looking & long lasting! Rigid foam insulation can’t be damaged by moisture and won’t degrade in appearance or R-value over time. In a crawl space, it’s usually installed against the interior face of foundation walls.

Rigid foam insulation performs exceedingly better than fiberglass in a crawl space. Rigid insulation is manufactured in panels of different thicknesses. Installers cut the panels to fit against the interior face of crawl space foundation walls. Panels are attached with adhesive or mechanical fasteners.

We typically insulate crawl space walls with foam board insulation. This brings the crawl space inside the building envelope, which improves overall home energy performance. This will also help make rooms above the crawl space more comfortable and can help lower heating and cooling bills.

Although rigid foam insulation is more expensive than fiberglass insulation up front, it’s actually less costly over time when you consider that you’ll never have to clean up or re-install a jumble of damaged, ineffective installation. Rigid foam will deliver the same performance and benefits years down the road as it does on day one.

Reed's Sprayfoam Insulation is your local crawl space insulation professional

Call 844-723-9296 or contact us online to schedule Free Estimate for basement or crawl space insulation in Georgetown, Lexington, Charleston, Johnson City, and nearby including Ashland, Richmond, Barboursville, Frankfort, Paintsville, Mt. Sterling, Huntington, and more. Reed's Sprayfoam Insulation is a trusted insulation company offering services in Hurricane, Nicholasville, Louisa, Middlesboro, Chesapeake, Somerset, South Point and nearby regions of Kentucky, West Virginia and Ohio, Tennessee.

Recent Crawl Space Insulation Jobs

Recently Completed Jobs

See AllOak Ridge, TN

Our crew first lined the uneven earth with gravel to help add some structure to the sloped path. Then lined the earth with a anti-microbial treated liner. The foundation walls were insulated with 2 inches of closed cell foam insulation. This will be ...

Waynoka, OH

Allen Junction, WV

Our crew sealed the saturated earth with a liner made of a 16 mil high and low-density polyethylene with polyester-cord reinforcement, the liner is treated with an antimicrobial finish that protects against mold and mildew growth on or under the l...

- Aberdeen

- Accoville

- Adams

- Addyston

- Adelphi

- Afton

- Ages Brookside

- Albany

- Alkol

- Allen

- Allen Junction

- Alpha

- Alum Creek

- Amberley

- Amelia

- Amesville

- Amherstdale

- Amigo

- Anawalt

- Andersonville

- Andover

- Annville

- Appalachia

- Apple Grove

- Argillite

- Arjay

- Arkoe

- Arlington Heights

- Arnoldsburg

- Artemus

- Arthur

- Ary

- Ashcamp

- Ashford

- Ashland

- Ashton

- Ashville

- Athalia

- Athens

- Augusta

- Auxier

- Avawam

- Avondale

- Bainbridge

- Baisden

- Bakersville

- Bancroft

- Banner

- Barboursville

- Barbourville

- Bartley

- Batavia

- Bath

- Baxter

- Bean Station

- Bear Branch

- Beattyville

- Beauty

- Beaver

- Beaver Pike Estates

- Bee

- Belcher

- Belfry

- Belle

- Belpre

- Ben Hur

- Benham

- Bentonville

- Berea

- Berry

- Berwind

- Bethel

- Bethelridge

- Betsy Layne

- Beverly

- Bevinsville

- Bexley

- Bidwell

- Big Creek

- Big Laurel

- Big Rock

- Big Sandy

- Big Stone Gap

- Bighill

- Bim

- Bimble

- Birchleaf

- Blackberry

- Blackey

- Blacklick Estates

- Blackwater

- Blaine

- Blair

- Bledsoe

- Bloomingrose

- Blount

- Blountville

- Blue Ash

- Blue Creek

- Blue Jay

- Blue River

- Bluff City

- Bob White

- Bobo

- Bonds Trailer Court

- Bonnyman

- Booneville

- Boons Camp

- Borderland

- Bourneville

- Bradfordsville

- Bradshaw

- Branchland

- Breaks

- Brecon

- Breeden

- Brenton

- Brice

- Briceville

- Bridgetown

- Bristol

- Bristol Village

- Brodhead

- Bronston

- Bruno

- Bryants Store

- Buchanan

- Buchtel

- Buckhorn

- Bud

- Buffalo

- Buford

- Bulan

- Bulls Gap

- Burdine

- Burkesville

- Burlington

- Burnside

- Burnsville

- Busy

- Butler

- Bybee

- Byington

- Bypro

- Cabin Creek

- Calvin

- Camp

- Camp Dennison

- Campbellsville

- Campton

- Canada

- Canal Winchester

- Cannon

- Carbon Hill

- Carlisle

- Carrie

- Caryville

- Catlettsburg

- Cawood

- Cedar Fork

- Cedar Grove

- Centerville Village

- Ceredo

- Chapmanville

- Chappell

- Charleston

- Chattaroy

- Chauncey

- Chavies

- Cherry Fork

- Cherry Grove

- Chesapeake

- Cheshire

- Cheviot

- Chillicothe

- Chilo

- Chuckey

- Church Hill

- Cincinnati

- Circleville

- Clairfield

- Clarksburg

- Clarktown

- Clay City

- Clayhole

- Clear Fork

- Clearfield

- Clendenin

- Cleves

- Clinchco

- Clinton

- Clintwood

- Closplint

- Clothier

- Coal Grove

- Coal Mountain

- Coalgood

- Coalton

- Coeburn

- Coldiron

- Coldstream CDP

- Columbus

- Combs

- Comettsville

- Comfort

- Commercial Point

- Concorde Hills CDP

- Coolville

- Coopersville

- Cora

- Corbin

- Corinne

- Corryton

- Cosby

- Costa

- Covedale

- Covel

- Crab Orchard

- Cranks

- Crommona

- Crown City

- Crum

- Cucumber

- Culloden

- Cumberland

- Cumberland Gap

- Cyclone

- Cynthiana

- Daleyville

- Dana

- Dandridge

- Danville

- Darbydale

- Darbyville

- Davenport

- David

- Davin

- Davy

- Dawes

- Dawsons MH Park

- Day Heights

- Dayhoit

- Deane

- Debord

- Deer Park

- Del Rio

- Delbarton

- Delhi Hills

- Delphia

- Delshire CDP

- Dema

- Denniston

- Dent

- Denton

- Derby

- Devola

- Dewitt

- Dice

- Dillonvale

- Dingess

- Dover

- Drift

- Dry Ridge

- Dry Run

- Drybranch

- Dryden

- Dublin

- Duff

- Duffeld

- Dunbar

- Dungannon

- Dunlap

- Dunlow

- Dunnville

- Dwale

- Dwarf

- Eagan

- East Bank

- East Bernstadt

- East Lynn

- East Point

- East Stone Gap

- Eastem

- Eckman

- Edgarton

- Eidson

- Elbert

- Eleanor

- Elgin

- Elizabethton

- Elizabethtown

- Elkfork

- Elkhorn

- Elkhorn City

- Elkview

- Elm Grove

- Elmwood Place

- Emerson

- Emmalena

- Eolia

- Ermine

- Erwin

- Eskdale

- Essie

- Ethel

- Eubank

- Evarts

- Evendale

- Ewing

- Ezel

- Fairfax

- Fairfield

- Falcon

- Fall Branch

- Falling Rock

- Falmouth

- Fanrock

- Fayetteville

- Fedscreek

- Felicity

- Ferguson

- Finneytown

- Fisty

- Flag Pond

- Flat Lick

- Flatgap

- Flatwoods

- Flemingsburg

- Forest Hills

- Forest Park

- Forestville

- Fort Blackmore

- Fort Gay

- Foster

- Fourmile

- Frakes

- Frametown

- Frankford

- Frankfort

- Franklin Furnace

- Fraziers Bottom

- Freebum

- Frenchburg

- Friendship

- Fruit Hill

- Gahanna

- Gallagher

- Gallipolis

- Gallipolis Ferry

- Gamer

- Garrett

- Garrison

- Gary

- Gate City

- Gatlinburg

- Gays Creek

- Genoa

- Georgetown

- Germantown

- Germany

- Gibson Trailer Park

- Gilbert

- Girdler

- Givens

- Glasgow

- Glen Fork

- Glen Jean

- Glen Rogers

- Glendale

- Glenwood

- Glouster

- Golf Manor

- Gordon

- Goshen

- Grandview

- Grandview Heights

- Gravel Switch

- Gray

- Grays Knob

- Grayson

- Green Acres

- Green Road

- Greeneville

- Greenfield

- Greenhills

- Greenup

- Greggs

- Greggs Hill

- Grethel

- Griffithsville

- Groesbeck

- Grooms MH Park

- Grove City

- Groveport

- Grundy

- Gulston

- Gunlock

- Hallie

- Hamden

- Hamersville

- Hamlin

- Hampton

- Handley

- Hanging Rock

- Hanover

- Hansford

- Hansoford

- Happy

- Hardy

- Hargerhill

- Harlan

- Harold

- Harrisburg

- Harrison

- Harrodsburg

- Harrogate

- Hartford

- Harts

- Hatch

- Haverhill

- Haydenville

- Haysi

- Hazard

- Hazel Green

- Heidrick

- Heiskell

- Helenwood

- Hellier

- Helton

- Hemshaw

- Henderson

- Henlawson

- Hensley

- Herndon

- Hewett

- Hi Hat

- Hide-A-Way Hills

- Higginsport

- Highland

- Highland Holiday

- Highpoint

- Hilliard

- Hillsboro

- Hiltons

- Hindman

- Hinkle

- Hitchins

- Hockingport

- Holden

- Holmes Mill

- Hometown

- Hooven

- Huber Ridge

- Huddy

- Hueysville

- Hugheston

- Hulen

- Huntington

- Huntsville

- Hurley

- Hurricane

- Hustonville

- Hyden

- Iaeger

- Idaho

- Ikes Fork

- Inez

- Ingram

- Institute

- Ironton

- Irvine

- Isaban

- Isom

- Isonville

- Itmann

- Ivel

- Jackhorn

- Jacksboro

- Jackson

- Jacksonville

- Jamestown

- Jasper

- Jeff

- Jefferson City

- Jeffersonville

- Jeffey

- Jellico

- Jenkinjones

- Jenkins

- Jeremiah

- Jesse

- Johnson City

- Jolo

- Jonesborough

- Jonesville

- Julian

- Junction City

- Justice

- Kanauga

- Keaton

- Keavy

- Keen Mountain

- Kenna

- Kenova

- Kenvir

- Kenwood

- Keokee

- Kermit

- Kerr

- Kettle Island

- Kiahsville

- Kilgore Estates

- Kimball

- Kimper

- Kincaid Springs

- Kings Mountain

- Kingsport

- Kingston

- Kistler

- Kite

- Kitts Hill

- Knoxville

- Kodak

- Kopperston

- Krypton

- Kyle

- Kyles Ford

- La Follette

- Lackey

- Ladd

- Lake

- Lake City

- Lake Darby

- Lake Lorelei CDP

- Lake View Heights

- Lake Waynoka CDP

- Lake White MH Park

- Lancaster

- Langley

- Lapperell

- Latham

- Laurel Bloomery

- Laurelville

- Lavalette

- Lawrenceburg

- Lebum

- Leesburg

- Lejunior

- Lenore

- Leon

- Lesage

- Letart

- Letcher

- Lewisburg

- Lexington

- Liberty

- Lick Creek

- Lily

- Limestone

- Lincoln Heights

- Lincoln Village

- Linefork

- Linn

- Littcarr

- Little Hocking

- Livingston

- Lockbourne

- Lockland

- Logan

- Logan Elm Village

- London

- Lone Mountain

- Lorado

- Lost Creek

- Louisa

- Loveland

- Loveland Park

- Lovely

- Lowell

- Lower Salem

- Lowmansville

- Loyall

- Lucasville

- Luttrell

- Lybum

- Lynch

- Lynchburg

- Lynco

- Maben

- Mack

- Macksburg

- Mackville

- Madeira

- Madison

- Majestic

- Mallie

- Mallory

- Mammoth

- Man

- Manchester

- Marble Cliff

- Marianna

- Mariemont

- Marietta

- Martha

- Martin

- Mary Alice

- Mascot

- Mason

- Matamoras Village

- Matewan

- Matheny

- Mavisdale

- Maxie

- Maybeury

- Mayking

- Maynardville

- Mayslick

- Maysville

- McAndrews

- McArthur

- McCarr

- McClure

- McDermott

- McDowell

- McGraws

- McKee

- McKinney

- McRoberts

- Meally

- Meane

- Means

- Melvin

- Miami

- Miami Heights

- Miamitown

- Miamiville

- Middleburg

- Middleport

- Middlesboro

- Midkiff

- Midway

- Milford

- Millfield

- Milligan College

- Millstone

- Milton

- Minerva

- Minerva Park

- Minford

- Minnie

- Miracle

- Mistletoe

- Mize

- Mohawk

- Monfort Heights

- Montgomery

- Monticello

- Moorefield

- Mooresburg

- Morehead

- Morgantown

- Morristown

- Moscow

- Mosheim

- Mount Alto

- Mount Carmel

- Mount Gay

- Mount Healthy

- Mount Healthy Heights

- mount lookout

- Mount Olivet

- Mount Orab

- Mount Repose

- Mount Sinai

- Mount Sterling

- Mount Vernon

- Mountain City

- Mountain Home

- Mousie

- Mouthcard

- Mowrystown

- Mozelle

- Mulberry

- Mullens

- Murray City

- Myra

- Nace Corner

- Nancy

- Naugatuck

- Nellis

- Nelsonville

- Neon

- Neville

- New Albany

- New Baltimore

- New Boston

- New Burlington

- New Haven

- New Holland

- New Market

- New Marshfield

- New Richmond

- New Tazewell

- Newcomb

- Newfain

- Newhall

- Newport

- Newtonsville

- Newtown

- Nicholasville

- Nickelsville

- Nitro

- Nora

- Norris

- North Bend

- North College Hill

- North Matewan

- North Spring

- Northbrook

- Northfork

- Northgate

- Norton

- Norwood

- Oak Hill

- Oak Ridge

- Oakwood

- Obetz

- Oceana

- Oil Springs

- Oilve Hill

- Olympia

- Omar

- Omega

- Ona

- Oneida

- Orgas

- Orient

- Orlando

- Ottawa

- Otway

- Owensville

- Owingsville

- Pageton

- Paint Lick

- Paintsville

- Panther

- Paris

- Parkers Lake

- Parksville

- Parrottsville

- Partridge

- Pathfork

- Patriot

- Paynesville

- Peach Creek

- Peck

- Pecks Mill

- Pedro

- Peebles

- Pennington Gap

- Perryville

- Peytona

- Phelps

- Phyllis

- Pickerington

- Pigeon Forge

- Pike

- Piketon

- Piketon Trailer Court

- Pikeville

- Pilgrim

- Pilgrims Knob

- Pinch

- Pine Knot

- Pine Ridge

- Pine Top

- Pineville

- Piney Flats

- Pinsonfork

- Pioneer

- Pippa Passes

- Pirates Cove

- Plainville

- Pleasant Hills

- Pleasant Run

- Pleasant Run Farm

- Pleasant Valley

- Poca

- Point Pleasant

- Pomeroy

- Pond Gap

- Poplar Grove

- Portsmouth

- Pound

- Powder Springs

- Powell

- Pratt

- Premier

- Premium

- Prestonsburg

- Prichard

- Printer

- Proctorville

- Pruden

- Putney

- Quincy

- R And J MH Park

- Raccoon

- Racine

- Ragland

- Ranger

- Ransom

- Rarden

- Raven

- Ravencliff

- Ravenna

- Rawl

- Raysal

- Reading

- Red House

- Red Jacket

- Redfox

- Regina

- Rehm

- Remington

- Reno

- Revelo

- Reynoldsburg

- Ricetown

- Richmond

- Richmond Dale

- Ridgeview

- Rio Grande

- Ripley

- River

- Riverdale

- Riverlea

- Riverview MH Park

- Riviera Park

- Roan Mountain

- Roark

- Robbins

- Robinson Creek

- Rock Camp

- Rock View

- Rockbridge

- Rockholds

- Rocky Fork Point

- Roderfield

- Rogers

- Rogersville

- Rome Village

- Rose Hill

- Rosemount

- Rossmoyne

- Rousseau

- Rowdy

- Rowe

- Roxana

- Royalton

- Rush

- Russell

- Russell Springs

- Russellville

- Rutland

- Rutledge

- Sabine

- Sadieville

- Saint Albans

- Saint Bernard

- Saint Charles

- Saint Martin

- Saint Paul

- Salem Heights

- Salt Lick

- Salvisa

- Salyersville

- Sandgap

- Sandstone

- Sandy Hook

- Sarah Ann

- Sardinia

- Sargents

- Sassafras

- Saul

- Saulsville

- Scalf

- Science Hill

- Scioto Furnace

- Sciotodale

- Scott Depot

- Scottown

- Scuddy

- Seaman

- Seco

- Seth

- Sevierville

- Sextons Creek

- Seymour

- Shady Valley

- Sharonville

- Sharples

- Sharps Chapel

- Sharpsburg

- Shawanee

- Shawnee CDP

- Shelbiana

- Shelby Gap

- Sherwood

- Shoals

- Shortt Gap

- Shyville

- Sidney

- Siler

- Silverton

- Simon

- Sinking Spring

- Sitka

- Sixteen Mile Stand

- Skyline Acres

- Slade

- Slemp

- Smilax

- Sneedville

- Sod

- Somerset

- Sophia

- South Bloomfield

- South Charleston

- South Point

- South Portsmouth

- South Salem

- South Shore

- South Webster

- South Williamson

- Southside

- sparta

- Speedwell

- Spellman Crossing

- Springdale

- Springfield

- Spurlockville

- Squire

- Staffordsville

- Stambaugh

- Stamping Ground

- Stanford

- Stanton

- Stanville

- Steams

- Steele

- Stephenson

- Stewart

- Stinnett

- Stockdale

- Stollings

- Stone

- Stoney Fork

- Stopover

- Strawberry Plains

- Strunk

- Sumerco

- Summerside

- Summersville

- Surgoinsville

- Switchback

- Switzer

- Sylvester

- Syracuse

- Tad

- Talbott

- Tarlton

- Tatesville

- Taylor Creek CDP

- Tazewell

- Teaberry

- Teays

- Telford

- Tennyson

- Terrace Park

- The Plains

- The Village Of Indian Hill

- Thelma

- Thorn Hill

- Thornton

- Thorpe

- Thousandsticks

- Thurman

- Tollesboro

- Tomahawk

- Topmost

- Tornado

- Totz

- Trade

- Tram

- Trimble

- Trosper

- Tuppers Plains

- Turpin Hills

- Turtle Creek

- Tutor Key

- Twilight

- Twin Mills MH Park

- Tyner

- Uneeda

- Unicoi

- Upper Arlington

- Urbancrest

- Valley View

- Van

- Van Lear

- Van Meter

- Vanceburg

- Vancleve

- Vansant

- Varney

- Verdunville

- Verner

- Versailles

- Vest

- Vicco

- Vincent

- Vinton

- Viper

- Virgie

- Waco

- Wakefield

- Walker

- Wallingford

- Wallins Creek

- War

- Warfield

- Warriormine

- Washburn

- Washington

- Watauga

- Waterford

- Waterloo

- Waverly

- Waverly Estates

- Waverly Gables

- Waverly Heights

- Waverly MH Park

- Waverly Place

- Wayland

- Wayne

- Waynesburg

- waynoka

- Webbville

- Weber City

- Weeksbury

- Welch

- Wellington

- Wellston

- Wendover

- West Columbia

- West Hamlin

- West Liberty

- West Portsmouth

- West Somerset

- West Union

- West Van Lear

- Westerville

- Wetmore

- Whamcliffe

- Wharton

- Wheelersburg

- Wheelwright

- Whick

- White Oak

- White Pine

- Whitehall

- Whitesburg

- Whitesville

- Whitewood

- Whitley City

- Whitman

- Wilcoe

- Wilkesville

- Wilkinson

- Williamsburg

- Williamson

- Williamsport

- Willow Wood

- Wilmore

- Wilsondale

- Winchester

- Windsor

- Winfield

- Winifrede

- Wise

- Withamsville

- Wittensville

- Wolford

- Woodbine

- Woodlawn

- Woodville

- Woollum

- Wooton

- Worthington

- Wurtland

- Wyco

- Wyoming

- Yawkey

- Yeaddiss

- Yerkes

- Yolyn

- Yosemite

- Zahns Corners

- Zaleski

- Zoe